Size this product for your application.

Our XSelector® program allows you to size products to help achieve optimum performance for your application. Use the online portal or try one of our mobile apps.

Hydraulic Oil Cooling

Air

Industrial

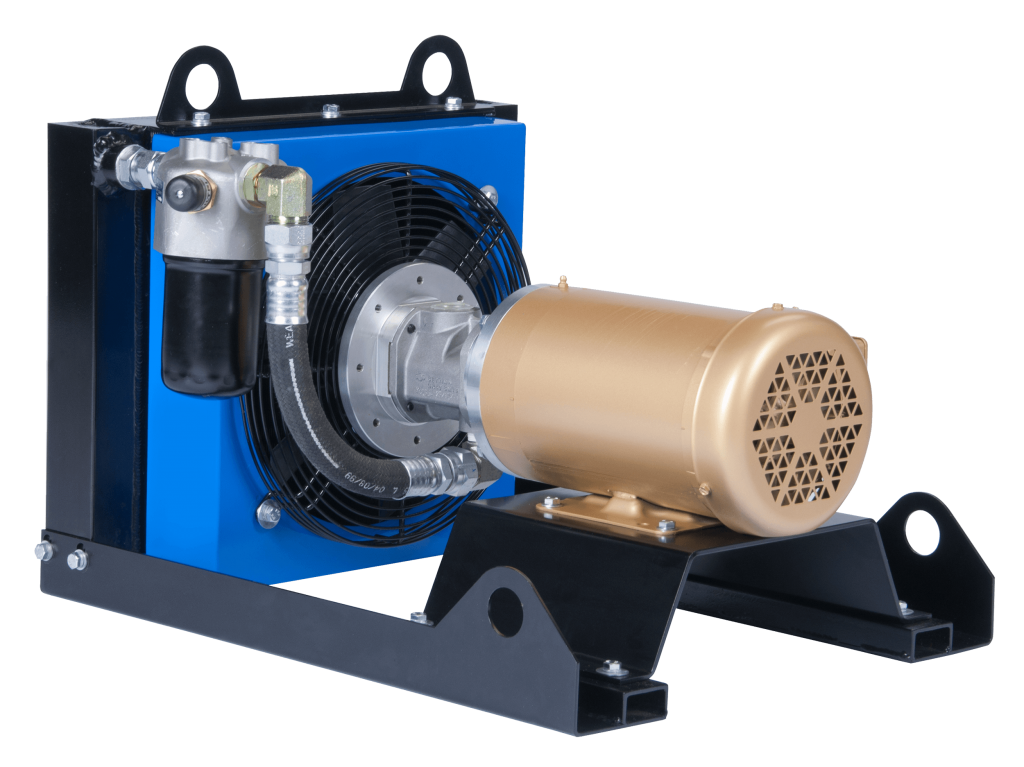

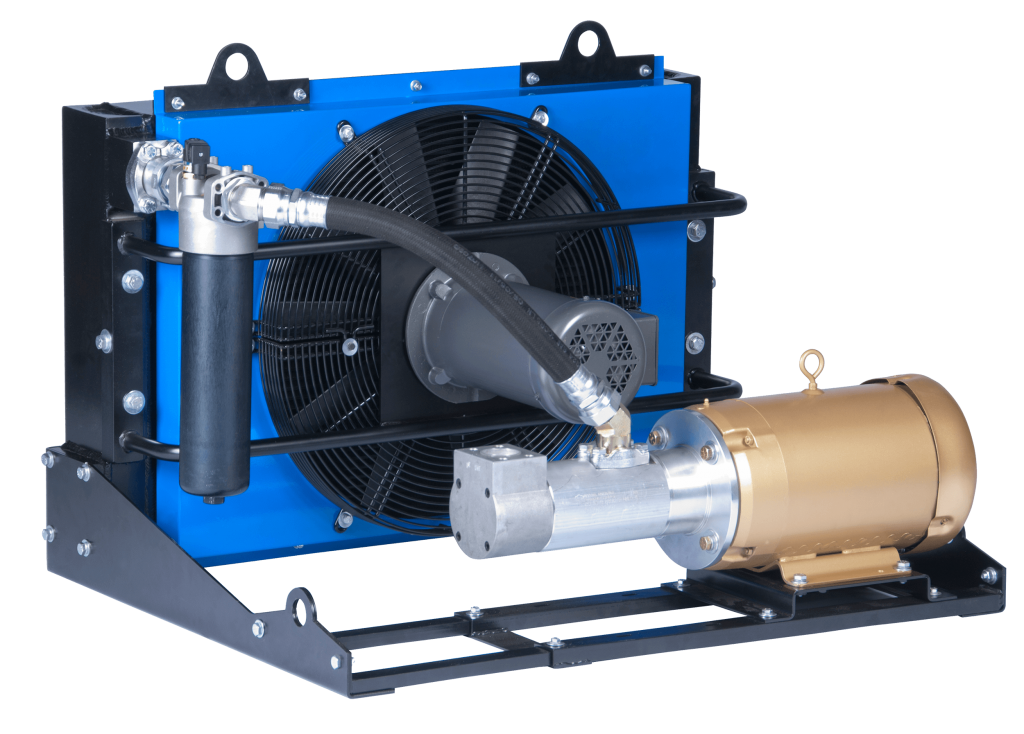

Air Cooled / Brazed Aluminum

The COL Series is an air cooled off-line fluid conditioning system utilizing reliable and high performing screw pump technology for independent cooling and filtering of system oils. Choose the standard brazed aluminum bar and plate core technology or the optional T-BAR™ core for high viscosity fluids. Other options include cartridge style in-line filters and thermostat temperature sensors.

Our XSelector® program allows you to size products to help achieve optimum performance for your application. Use the online portal or try one of our mobile apps.

* To register for XSelector® please go to www.thermaltransfer.com/get-in-touch/ and complete the XSelector® Inquiry form and submit.

Download the XSelector® for both Apple and Android formats by searching for XSelector® in their App Stores. You must first register for XSelector® before using it on mobile devices.